National Lubricating Grease Institute (NLGI)

- The National Lubricating Grease Institute (USA) developed a classification of lubricants that has acquired international status.The first parameter that the classification of the same name operates with is the “grease consistency” (in simple terms, the degree of its thickness).

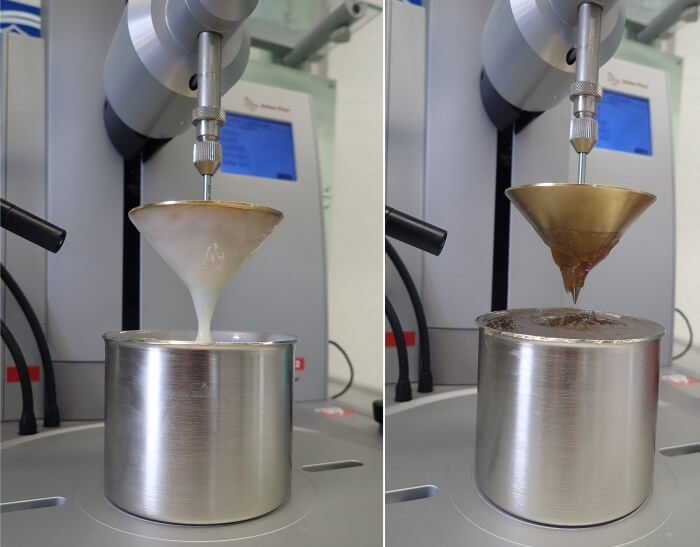

According to the institute's methodology, the density is measured using the laboratory method of "working penetration". This parameter is determined using a penetrometer with a cone, which is lowered into the lubricant for five seconds at a temperature of 25°C. The depth of the cone's immersion is measured and expressed in tenths of a millimeter. . Penetration is usually determined for both mixed and unmixed grease. The difference between these indicators characterizes the stability of the grease and its ability to withstand mechanical loads. In addition, the higher the numerical value of penetration, the softer the grease.

Content

NLGI automotive lubricant quality category

NLGI LA • NLGI LB • NLGI GA • NLGI GB • NLGI GC

NLGI LA category greases

They are used for lubricating chassis elements and articulated joints of passenger cars and other light-duty vehicles.

Quality requirements

Lubricants must satisfactorily lubricate the chassis components and joints with frequent lubrication changes (in passenger cars, every 3,200 km or more often). Lubricants must be resistant to oxidation and changes in consistency, and also protect joints and other chassis components from corrosion and wear in low load conditions. Generally NLGI 2 greases are recommended , but other NLGI grades can also be used .

NLGI LB Category Greases

They are used to lubricate the chassis components and articulated joints of cars, trucks and other vehicles operating in both light and heavy duty conditions. Heavy duty conditions are those with long lubrication change intervals, high loads, vibrations, exposure to water or other contaminants. These are the highest quality lubricants for chassis.

Quality requirements

Lubricants must satisfactorily lubricate the chassis elements and articulated joints at temperatures from -40 to +120 C with an extended lubrication change interval (in passenger cars over 3200 km). Lubricants must be resistant to oxidation and changes in consistency, and also protect the chassis elements and hinges from corrosion and wear, even under the influence of dirt and heavy loads. Generally, greases of NLGI 2 consistency are recommended, but greases of other NLGI grades can also be used .

NLGI GA Category Greases

They are used for lubricating wheel bearings of cars, trucks and other vehicles operating in light duty conditions with frequent lubricant changes under normal operating conditions.

Quality requirements

Lubricants must satisfactorily lubricate bearings at a limited temperature from -20 to +70 C. There are no additional requirements.

NLGI GB Category Greases

Used to lubricate wheel bearings of cars, trucks and other vehicles operating in both light and moderate conditions. Moderate conditions are the normal operating conditions found in most vehicles.

Quality requirementsLubricants must lubricate satisfactorily in a wide range of temperatures from -40 to +120 and even up to +160 C. Lubricants must be resistant to oxidation, evaporation, changes in consistency, and protect bearings well from corrosion and wear. Lubricants of NLGI 2 consistency are usually recommended, but lubricants of other NLGI grades - NLGI 1 and NLGI 3 - can also be used .

NLGI GC Category Greases

They are used to lubricate wheel bearings of cars, trucks and other vehicles operating in both light and heavy duty conditions. Heavy duty conditions are found in vehicles whose bearings are subject to high temperatures. These are vehicles with disc brakes that operate in stop-start mode (buses, taxis, city police cars, etc.) or heavy braking mode (towing, heavy driving in the mountains, etc.). These are currently the highest quality lubricants for wheel bearings.

Quality requirements

Lubricants must lubricate satisfactorily in a wide range of temperatures from -40 to +160 and even up to +200 C. Lubricants must be resistant to oxidation, evaporation, changes in consistency, and protect bearings well from corrosion and wear. Lubricants of NLGI 2 consistency are usually recommended, but NLGI - NLGI 1 and NLGI 3 lubricants can also be used .

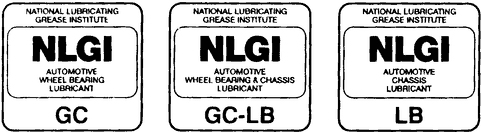

Designations

To designate categories of lubricants, NLGI uses a sign - the NLGI symbol, which is assigned only to lubricants of the highest category: GC , LB and GC-LB ( Fig. 1 ). Lubricants of other categories are not designated by this sign, only on the label or in the description are usually indicated the symbols of the category NLGI GA , NLGI GB , NLGI LA . In Europe, the American system of designation of automotive lubricants, based on the purpose, is rarely used, and there is no similar European system.

Fig. 1. NLGI category conformity marks.

Mandatory tests for determining NLGI categories

ASTM | Tests | LA | L.B. | GA | GB | GC |

D 217 | Penetration | + | + | + | + | + |

D 566 | Dropping point temperature | + | + | + | + | + |

D 1264 | Washing with water | - | - | - | + | + |

D 1742 | Oil release temperature | - | + | - | + | + |

D 1743 | Rust prevention | - | + | - | + | + |

D 2266 | Wear and tear at the ChMShT | + | + | - | + | + |

D 2596 | Maximum pressure on the ChMShT | - | + | - | - | + |

D 3527 | Resistance to high temperature | - | - | - | + | + |

D 4170 | Pitting wear | - | + | - | + | + |

D 4289 | Compatibility with elastomers | + | + | - | + | + |

D 4290 | Fluidity | - | - | - | + | + |

D 4693 | Low temperature torque | - | + | + | + | + |

NLGI Classifications

According to the NLGI classification , greases are divided into classes depending on the level of penetration - the higher the numerical value of penetration, the softer the grease. The NLGI classification of plastic greases by consistency is given in Table 2 (corresponds to grades according to DIN 51818. DIN is the German Standards Institute).

There are nine categories - from 000 to 6:

• Category 2 is the consistency that is most widely used;

• Categories 000 and 00 are semi-liquid lubricants used as an alternative to oils in mechanisms and centralized lubrication systems with a small cross-section of supply channels (for example, in modern trucks);

• 0 and 1 - categories for use in main centralized lubrication systems (e.g. industrial equipment, trucks);

• Categories 2 and 3 are used primarily for bearing lubrication;

• Categories 4 and 6 represent extremely thick greases and are rarely used except in special cases of “grease blocks”.

Note : Plastic lubricants used in passenger cars generally belong to the second class.

NLGI grade | Penetration Index (0.1 mm) | ISO 2137 consistency | Scope of application |

000 | 445-475 | very liquid | closed gear transmissions |

00 | 400-430 | liquid | |

0 | 355-385 | semi-liquid | central lubrication systems |

1 | 310-340 | very soft | |

2 | 265-295 | soft | ball/roller bearings |

3 | semi-solid | high speed bearings | |

4 | 175-205 | solid | |

5 | 130-160 | very hard | open gear drives |

6 | 85-115 | extra hard |