Product Description

Mobilux™ EP 0 , 1 , 2 , 3 , 004 and 023 are part of a family of high performance greases that includes four general-purpose industrial greases and two specialty semi-fluid greases. These lithium hydroxystearate thickened greases provide outstanding protection against wear, rust and water washout. They are available in NLGI grades 00 to 3 with ISO VG 150 and 320 base oil viscosity grades . Mobilux EP 0 , 1 , 2 and 3 greases are recommended for most types of industrial equipment, including heavy-duty equipment subject to high specific pressures or shock loading. These greases provide excellent rust and corrosion protection and resist water washout, making them ideal for use in equipment operating in wet conditions. Mobilux EP 0 and 1 are suitable for centralised lubrication systems. Mobilux EP 2 and 3 are general purpose greases. The recommended operating temperature range is -20° to 130°C, but they can also be used at higher temperatures provided the lubrication frequency is increased accordingly. Mobilux EP 004 and Mobilux EP 023 are specifically designed for the lubrication of enclosed gearboxes and bearings in non-hermetic housings; they can also be used in other industrial equipment where conventional gear oils are not retained in the gearbox housing, chain case, etc. due to leakage due to worn or missing seals. The recommended operating temperature range is -20° to 120°C for Mobilux EP 004 and -20° to 120°C for Mobilux EP 023.

Features and Benefits

Mobilux EP greases have a long history of successful use and have demonstrated good performance in terms of corrosion protection, low temperature pumpability and high temperature service life.

The 40 lb Timken Friction Machine test confirms their ability to withstand loads and extreme pressures.

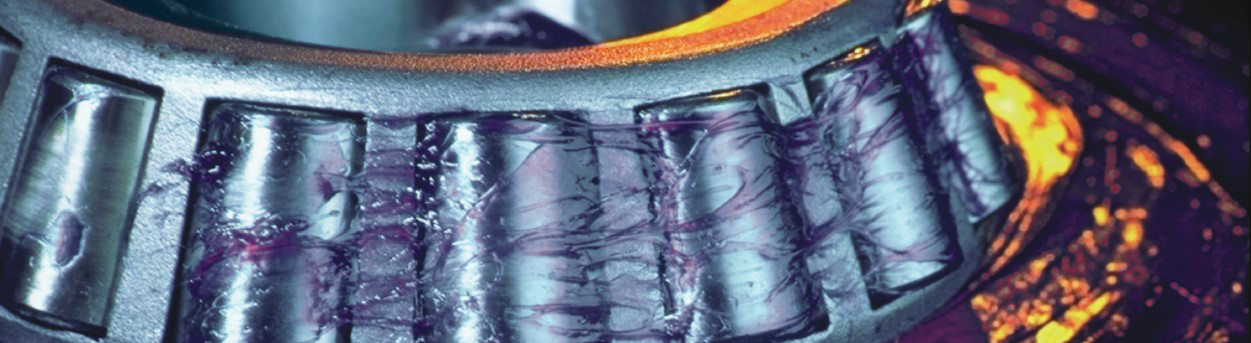

• Reduced wear under heavy or shock loading and vibration conditions to ensure equipment reliability and availability.

• Rust and corrosion protection, water washout resistance for protection and good lubrication of equipment even in the presence of water.

• Extend bearing life in wet conditions to reduce bearing costs and prevent unexpected downtime.

• Good pumpability in centralised lubrication systems ( Mobilux EP 0 and 1 ). • Effective leak prevention ( Mobilux EP 004 and Mobilux EP 023).

Application

• Mobilux EP 0 and Mobilux EP 1 greases provide good pumpability at low temperatures and are suitable for use in centralized lubrication systems and other systems where good low-temperature performance is required.

• Mobilux EP 2 is recommended as a general purpose lubricant for anti-friction and plain bearings, bushings and pins under normal operating conditions.

• Mobilux EP 3 is a thicker NLGI grade 3 grease recommended for use where maximum protection against water or solid contaminants is required.

• Mobilux EP 004 and Mobilux EP 023 are particularly suitable for the lubrication of enclosed gearboxes and bearings in poorly sealed housings on most types of underground mining equipment, with the exception of electric motor gears. Mobilux EP 004 and Mobilux EP 023 can also be used in many other industrial applications where conventional gear oils cannot be retained in gearbox housings, chain cases, etc. due to leakage due to worn or missing seals.

Specifications and approvals

The product meets or exceeds the following requirements: | MOBILUX EP 023 | |||||

DIN 51825:2004-06 - KP 1 K -20 | X | |||||

DIN 51825:2004-06 - KP 2 K -20 | X | |||||

DIN 51825:2004-06 - KP 3 K -20 | X | |||||

DIN 51826:2005-01 - GP 000 G -20 | X | |||||

DIN 51826:2005-01 - GP 00 G -20 | X | |||||

DIN 51826:2005-01 - GP 0 G -20 | X |

Properties and characteristics

Property | MOBILUX EP 023 | |||||

Class | NLGI 0 | NLGI 1 | NLGI 2 | NLGI 3 | NLGI 00 | NLGI 000 |

Thickener type | Lithium | Lithium | Lithium | Lithium | Lithium | Lithium |

Base oil viscosity of lubricants at 40°C, mm2/s, AMS 1697 | 160 | 160 | 160 | 160 | 160 | 320 |

Color, visually | BROWN | BROWN | BROWN | BROWN | BROWN | BROWN |

Dropping point, ºC, ASTM D 2265 | 190 | 190 | 190 | 190 | ||

4-Ball Anti-Scuffing Test, Weld Load, Kgf, ASTM D2596 | 250 | 250 | ||||

4-Ball EP Test, Weld Point, Kgf, ASTM D2596 | 250 | 250 | 250 | 250 | ||

4-Ball Wear Test, Wear Scar Diameter, mm, ASTM D2266 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

4-Ball Wear Test, Scar Diameter, 40 kg, 1200 rpm, 1 hour, 75 C, mm, ASTM D2266 | 0.5 | |||||

Penetration, 60X, 0.1 mm, ASTM D217 | 370 | 325 | 280 | 235 | 415 | 460 |

SKF Rust Test, Distilled Water, ASTM D6138 | 0-0 | 0-0 | ||||

SKF Rust Test, Bearing 1, Distilled Water, ASTM D6138 | 0 | 0 | 0 | 0 | ||

SKF Rust Test, Bearing 2, Distilled Water, ASTM D6138 | 0 | 0 | 0 | 0 | ||

Timken Friction Test Load Limit, kg, ASTM D 2509 | 40 | 40 | 40 | 40 | 40 | 40 |